length between vickers hardness tests on weld|vickers pyramid hardness test : retailer The Vickers hardness test at a glance: Ideal for micro hardness testing. Can be used for case hardness depth measurement, Jominy testing and hardness testing of welds. Standards: ASTM E384, ISO 6507 and JIS Z 2244. See our . Autoclaved aerated concrete (AAC) is a type of precast concrete with an expansion agent that rises the mixture, similar to yeast in bread dough. Once cured, this type of concrete contains about 80% air.Z-Value is the number of degrees of temperature change necessary to change the D-Value by a Factor of 10. For example, if D-Value at 121ºC is 1.5 min & Z-Value is 10ºC. Then D-Value at 131ºC will be 0.15 minute.

{plog:ftitle_list}

The OM-CP-PRTEMP140 is a high temperature and pressure data logger all in one, created specifically for use in autoclave validation, mapping studies and pressurized processes.

The Vickers hardness test at a glance: Ideal for micro hardness testing. Can be used for case hardness depth measurement, Jominy testing and hardness testing of welds. Standards: ASTM E384, ISO 6507 and JIS Z 2244. See our .The recommended Vickers hardness range can be found in the standard and standard ASTM E384. Depending on the test force and specimen material used, the Vickers hardness value .

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series .

laboratory autoclave services inc seattle w

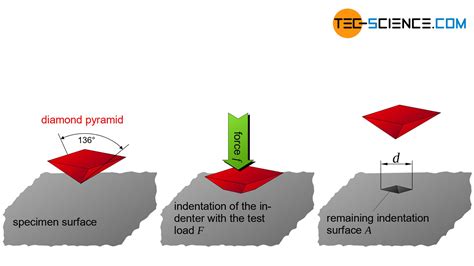

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.This document specifies the procedures for the hardness testing of etched cross-sections of resistance spot, projection, and seam welds. The aim of the hardness tests is to determine the .This is one of the oldest hardness testing methods, and has a wide hardness scale, making it suitable for most metals and welds. The Vickers hardness test uses a 136° pyramidal diamond .For the Knoop hardness test, the length of the long diagonal is measured, which is used to derive the Knoop hardness value. For micro indentation testing, the indenter shall contact the .

The Vickers hardness test at a glance: Ideal for micro hardness testing. Can be used for case hardness depth measurement, Jominy testing and hardness testing of welds. Standards: .

vickers pyramid hardness test

The recommended Vickers hardness range can be found in the standard and standard ASTM E384. Depending on the test force and specimen material used, the Vickers hardness value .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series .

The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) .This document specifies the procedures for the hardness testing of etched cross-sections of resistance spot, projection, and seam welds. The aim of the hardness tests is to determine the .

This is one of the oldest hardness testing methods, and has a wide hardness scale, making it suitable for most metals and welds. The Vickers hardness test uses a 136° pyramidal diamond .

For the Knoop hardness test, the length of the long diagonal is measured, which is used to derive the Knoop hardness value. For micro indentation testing, the indenter shall contact the .The Vickers hardness test is widely used for testing welds because the size of the indentation is small and it is easy to locate in specific regions of the weld such as weld metal, HAZ and base .

Vickers hardness tests use a square pyramid shaped diamond indenter and a load ranging from 1 to 120 kg. Vickers indentation is smaller than the Brinell impression, thus far .

Vickers hardness test, and ISO 4545, ISO 4546 and ISO 4547 for the Knoop hardness test. Testing is carried out to determine the range of hardness values in the parent metal (both .The Vickers hardness test at a glance: Ideal for micro hardness testing. Can be used for case hardness depth measurement, Jominy testing and hardness testing of welds. Standards: .The recommended Vickers hardness range can be found in the standard and standard ASTM E384. Depending on the test force and specimen material used, the Vickers hardness value .

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series .The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) .

laboratory autoclave services inc seattle wa

This document specifies the procedures for the hardness testing of etched cross-sections of resistance spot, projection, and seam welds. The aim of the hardness tests is to determine the .This is one of the oldest hardness testing methods, and has a wide hardness scale, making it suitable for most metals and welds. The Vickers hardness test uses a 136° pyramidal diamond .For the Knoop hardness test, the length of the long diagonal is measured, which is used to derive the Knoop hardness value. For micro indentation testing, the indenter shall contact the .The Vickers hardness test is widely used for testing welds because the size of the indentation is small and it is easy to locate in specific regions of the weld such as weld metal, HAZ and base .

Vickers hardness tests use a square pyramid shaped diamond indenter and a load ranging from 1 to 120 kg. Vickers indentation is smaller than the Brinell impression, thus far .

vickers micro hardness test

vickers hardness testing time

laboratory autoclave servicing and maintenance

vickers hardness testing procedure

Available sizes are 1/16”, 1/8”, 1/4”, 3/8”, & 1/2”. Fittings manufactured from cold worked 316 stainless steel. Tubing is manufactured from annealed stainless steel.

length between vickers hardness tests on weld|vickers pyramid hardness test